|

Business Field - Cleaning

|

|

● Development Overview (Patent Application NO : PJC20891)

|

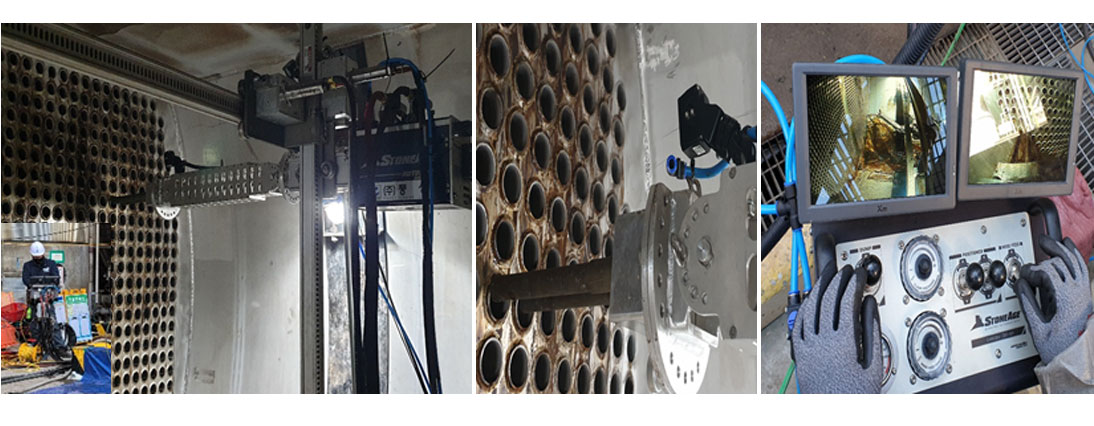

- Install cleaning equipment inside by using Jet Pump Equipment, Implement cleaning while watching and controlling inside with the camera attached outside

controller

- No internal monitoring required

- Excellent cleaning quality with equal forward/rearward speed

- Achieve superior safety accident prevention by not exposing to chemicals and gases through outside control method

- Improve work time by 25% compared to manual cleaning

- Reduce the amount of industrial water and waste water by 25% compared to manual cleaning

|

|

|

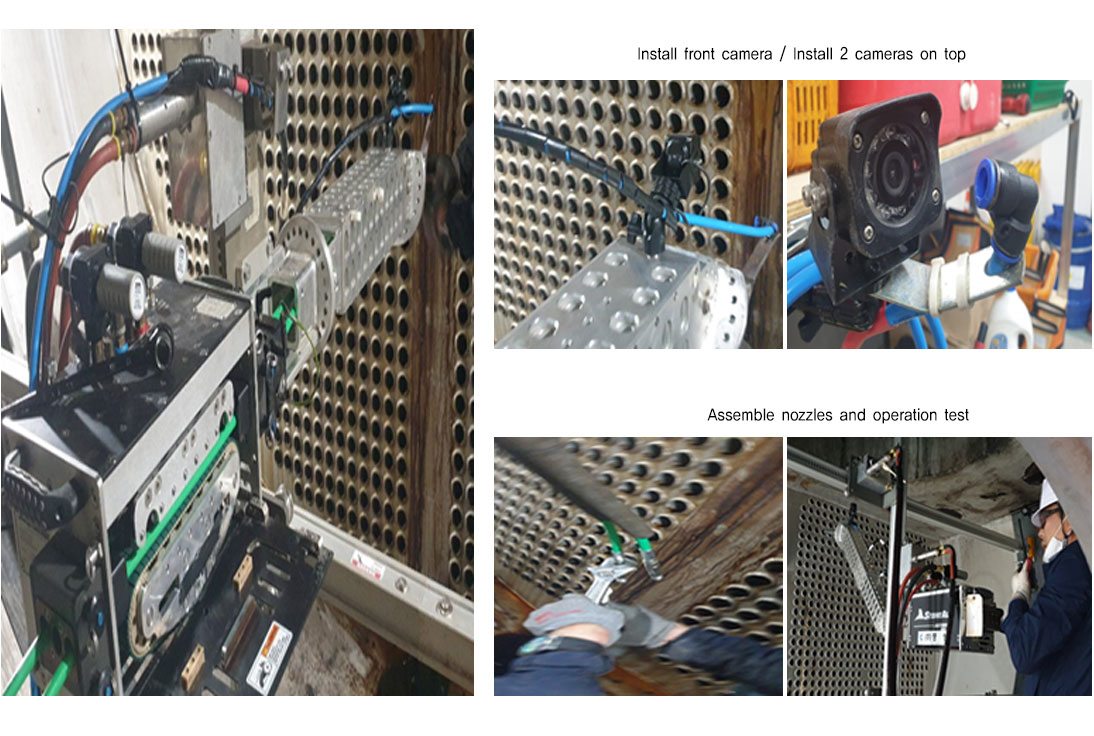

● Equipment Operation

|

|

|

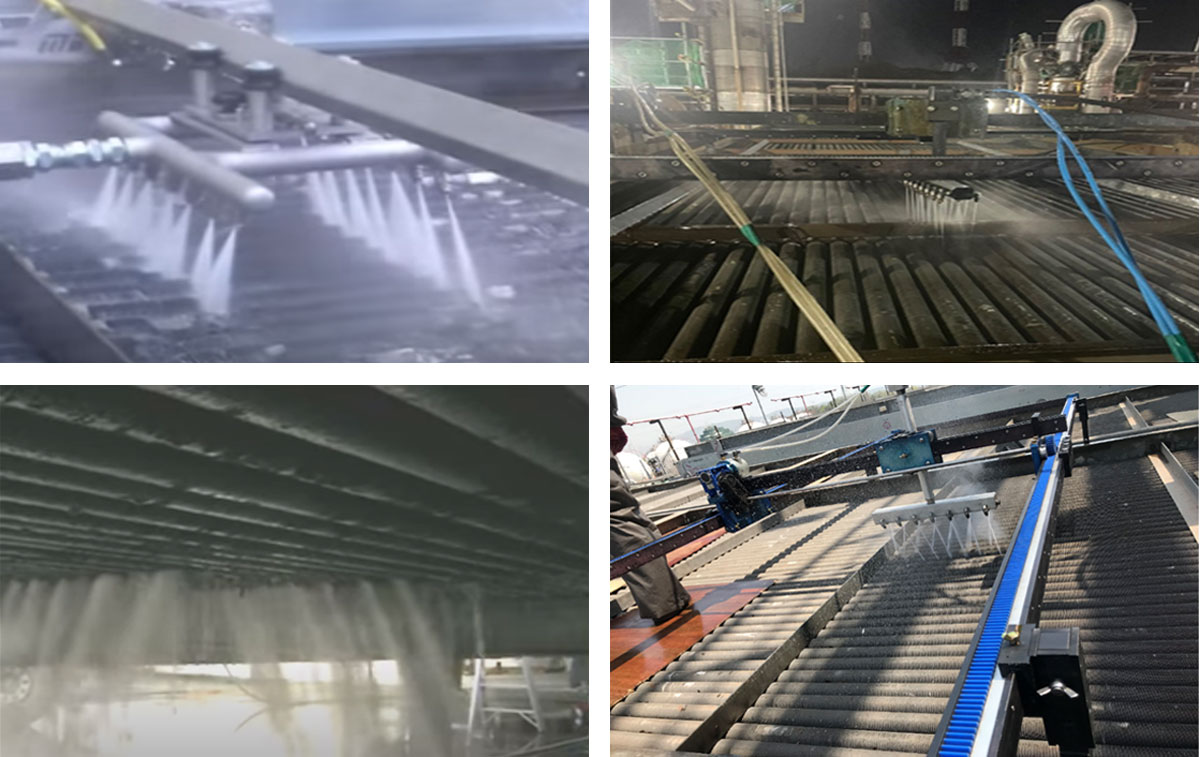

● Auto Jet Cleaning Work Results by Process

|

|

|

● Auto Jet Cleaning Operation

|

|

|

● Background of Development Promotion

|

|

Problems of existing work method

|

- Fatigue increase and efficiency decrease of laborers by work progress

- uneven quality by each engineer’s degree of proficiency

- Difficulty in securing engineers by the avoidance of 3D industry and

aging

- Safety accident Occurrence (Recently many fatal accidents and safety

accidents arise.)

- A number of complaints for the noise during the work

Existing Work (Manual)

|

|

|

|

Advantages of Automation System

|

- Improvement of work efficiency / Reduction of Operation Period

- Securing volume and quality of work

- Problem-Solving

- Prevention of safety accident

- Minimize the noise

Automation operations

|

|

|

|

● Photographs of Equipment

|

|

|

● Operation Standard ? Things to prepare

|

Things to prepare before Jet Cleaning

1) All workers set to work after completing safety education and specialized medical examination.

2) Workers commence work after receiving documented permission for operation of production in work request.

3) Education for MSDS material and training for skills to deal with accidents such as skin contact and inhalation

4) Identify evacuation route and secure evacuation route around the workplace

5) Commence work after confirming protective gears (e.g. safety belt)

6) A supervisor and a safety manager should be present at work site and actions not to damage surrounding facilities should be taken before setting to work.

7) Waste water should be collected in a scatter proof tent, transferred to designated site guided by tent hose in the presence of SK supervisor

Things to prepare during task

1) Personal protective gears such as face mask, acid-resistant clothes, safety boots, safety belt, etc

2) Lighting facilities for night work

3) Installation of tent hose and scatter proof tent for waste water

4) Confirm the operation status of cleaning device (Water Jet Pump) and other devices developed uniquely.

5) Choose nozzles appropriate to the internal condition of TUBE and selectively arrange them according to Jet Pump quantity.

6) Check the operation status of the fan and make sure the switch is off when working with external fan

7) Waste water should be collected in a scatter proof tent, transferred to designated site guided by tent hose in the presence of SK supervisor

Things to prepare for work safety

1) Install hazard marking tape at the bottom of cleaning bundle and assign emergency personnel to control the access to the bottom

2) Cleaning engineer must wear personal safety gears like face mask to protect himself/herself from sludge contamination and skin damage.

3) Secure evacuation route by cleaning up around the workplace before the task

4) Place the MSDS material in a well-visible place and notify the field operator of the risk.

5) In principle strictly ban the simultaneous operation of top and bottom and confirm other operations before starting the task

6) Scattering proof tent and waste water are guided to the designated place and set to work after consulting with supervisor.

7) For the risk management the manager carries out pre-inspection before work and commence task after issuing a work permit.

|

|

● Operation Standard - Cleaning

|

|

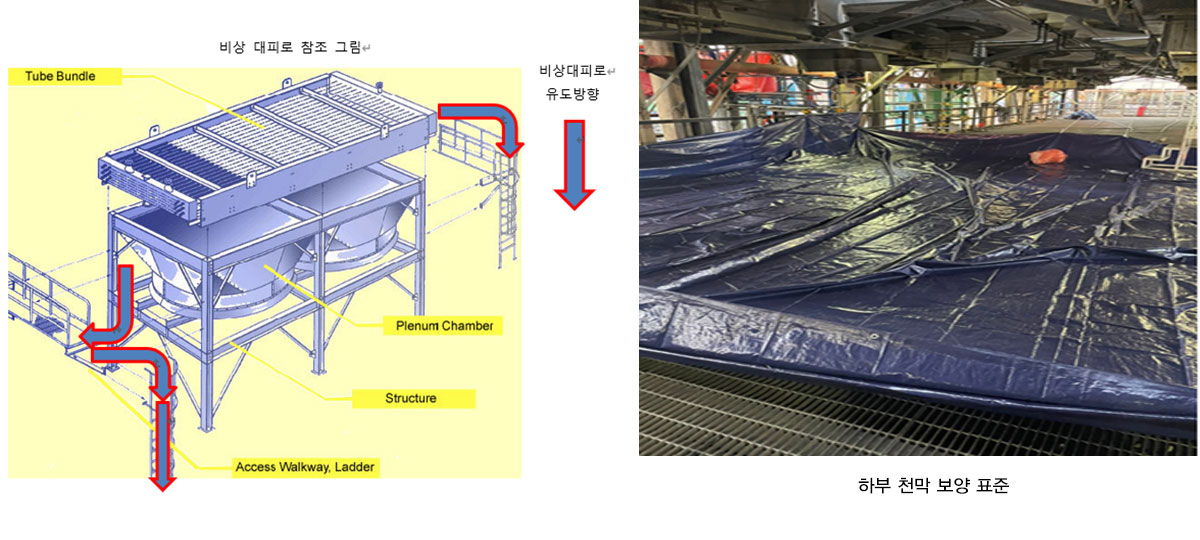

1.Installation of wastewater receiving tent under air fan cooler

|

|

|

|

2. Installation of agricultural hoses to transfer wastewater to the designated place

|

|

|

| |

|

3. Adjust the working pressure according to the condition of cleaning object (over 100Bar)

|

|

|

|

4. Implement cleaning

|

|

|

|

|

● Scope of Application

|

Refuel LINE, Hydraulic LINE, LOU LINE, SUS LINE, Oxygen Piping, BOILER Slender Piping

|

|

● Object

|

To remove oil, moisture, and other scales formed inside PIPE and various mechanical devices

|

|

● Order of operation for Chemical Cleaning

|

Installation of temporal pipes → Sealing test → Degreasing (removing oil and residue) → Flushing (removing degreasing liquid and residue) → Acid cleaning (organic or inorganic acid) → Flushing → Anticorrosion → Inspection → Drying → Nitrogen purge → Wastewater disposal

|

|

|

No

|

Process

|

Category

|

Measurement Method

|

Measurement cycle

|

Note

|

|

|

1

|

Temporal pipe

|

LEAK TEST

|

Observation Soapy water test

|

Upon Completion

|

|

|

|

2

|

FLUSHING

|

Turbidity / Contamination

|

Observation / Confirmation of sediment

|

30 minutes

|

|

|

|

3

|

Degreasing

|

Oil content

Turbidity

Concentration of chemicals

|

Drying

Observation

Neutralization Titration

|

2hours

1hours

1hours

|

|

|

|

4

|

Acid-cleansing

|

Concentration of chemicals

PH

T-Fe Ion Concentration

Corrosion Rate(%)

Turbidity

Circulation Time

|

Neutralization Titration

Tester and Litmus

Tester and Titrimetry

Drying using specimen

Observation

|

30 minutes

30 minutes

1 hour

1 hour

1 hour

|

Citric acid 4~6%

Below 3 degree

2~3 hours

|

|

|

|

● Precautions for each process

|

|

1. Installation of temporal pipes and Sealing test

|

1) Connect to the equipment after installing chemical pump

2) Select connecting hose as steel pipe or rubber hose according to the chemical content

3) Implement leakage test after Connecting the pump to the equipment to be chemical cleaning

4) Immediately correct pipe link and block the valve when occurring leakage

Immediately correct pipe link and block the valve when occurring leakage

|

|

2. Degreasing

|

1) Fill the degreasing fluid accurately according to the specifications and check the temperature.

2) Dilute rust preventing liquid (Enclosed with penetrant-surfactant MSDS. Enclosed with Corrosion inhibitor IBIT30AR.MSDS. Enclosed with antioxidant N2H4 MSDS)

3) Circulate through pump to the facility to be chemical cleaning (12 to 24 hours depending on condition)

4) Examine leakage thoroughly around the temporal pipes and equipment

5) Execute flushing after confirming the scale is softened enough

< Injection of chemical cleaning solution >

|

|

3. Flushing

|

1) Fill the facilities to be cleaned and pump with enough water before circulating

2) Control the valve to circulate during flushing by operating injection pump (circulation and reverse circulation)

3) Lock the drain valve and make it circulate normally.

4) ) Examine carefully that there is no leakage around the valve and temporal pipes.

< Chemical Cleaning Operation >

|

|

4. Acid Cleaning (Circulation Method)

|

1) Always maintain the same temperature as room temperature(18℃) (Chemical: Citric Acid, Enclosed with MSDS )

2) Circulate until the ion concentration is constant. (takes 2~3 hours depending on the condition)

3) Windproof measures must be taken not to allow foreign matter (e.g. sand, dust.) in the acid cleaning tub

4) Chemical concentration must be checked when injected in the acid cleaning tub during and before operation.

5) Inhibit diffusion of hydrogen generated by acid cleaning, and flame is strictly prohibited. Influence of acidic residue must not be left after flushing

6) 검사는 배관재질의 시편을 사용 부식률감량을 측정하여 시간과 약품농도를 측정한 후 조절한다.

|

|

5. Neutralization and Anticorrosion

|

1) Maintain temperature and PH constantly. (PH12~14)

2) Protective film should be formed while execute immersion neutralization at 40~50°C.

3) When concentration reduced below standard, supplement chemicals while measuring concentration

4) Drain after implementing anticorrosion for 2~3 hours.

5) When conducting inspection, client and supervisor conduct mutual visual inspection, and inspection equipment is used if necessary.

|

|

6. Inspection

|

Analyze and examine chemical cleaning

< Inspection Item: PH, T-Fe Ion Concentration, Turbidity, Oil Content >

|

|

7. Wastewater Disposal

|

< Transfer to wastewater treatment facility >

|

|

8. Sedimentation Method

|

< Chemical Cleaning Operation>

|

|

◆ Classification of Chemical Cleaning

|

· Precipitator Meth

Used for part of device that cleaning chemical cannot pass through due to its structure or for equipment that cannot be cleaned chemically. Difficult to adjust the concentration and temperature of chemical, and corrosion rate cannot be guaranteed.

. Spray Method

Used to reduce costs and increase scale removal efficiency when cleaning containers, tanks, etc. Cannot be applied to other equipment due to hydrogen embrittlement and severe erosion by oxygen.

|

|

● Scope of Application

|

After operation of long-distance pipes, underground burial pipes that vent or drain cannot be installed, ultra-high-pressure pipes and gas pipes (oxygen, nitrogen, hydrogen, etc.), the method is utilized by using specialized cleaning device that exploiting air, nitrogen, water or chemical depending on the condition to get rid of rust and foreign matter in the pipes. Select cleaning method and implement it by establishing detailed plan according to the condition such as process, demand, material or fluid.

|

|

● Purpose

|

A. Removal of foreign matter in pipe such as pieces of wood and metal, welding rods, cloth, sand, and mud when operating.

B. Decrease fluid resistance by minimizing roughness of pipe surface.

C. Provide complete cleaning by preventing pollution in the pipe.

|

|

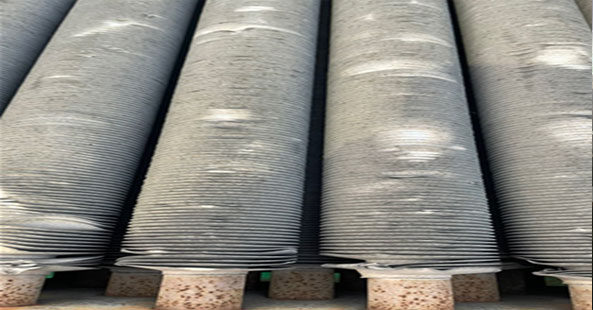

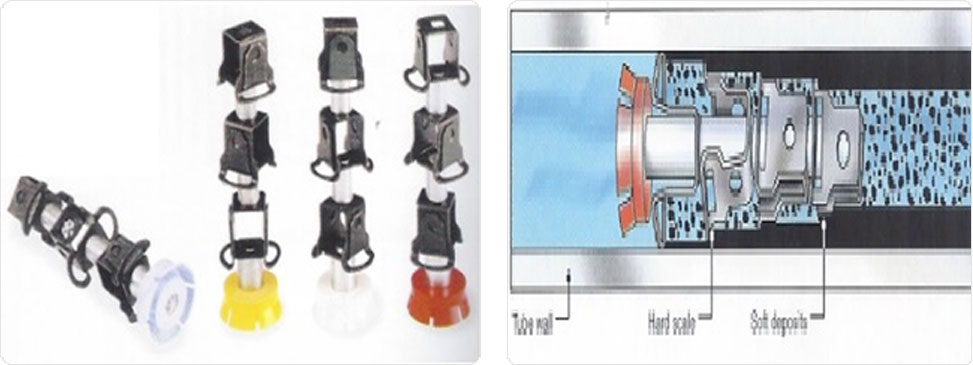

● Type of PIG

|

Selecting appropriate PIG Type is essential as it results in budget reduction, shortening operation period, etc

A. FOAM PIG

B. SHAFT PIG

C. SPHERES

D. INTELLIGENT

E. SUITABLE PIGS FOR CLEANING LONG DISTANT PIPELINES

|

|

● Operation Procedure of PIG

|

1. Examine state of the pipe with on-site supervisor and select PIG type.

2. Install launch tube appropriate to size of the pipe.

3. Insert PIG in launch tube and launch PIG.

4. Check the state of PIG after launching and repeat launching.

5. Examine condition of inside of the pipe with supervisor and complete operation.

|

|

● Precautions for PIG

|

1. Select PIG that is 5 to 10mm larger than pipe size

2. Request inspection after firing one sponge PIG, two urethane PIGs, and finally five sponge PIGs in order.

|

|

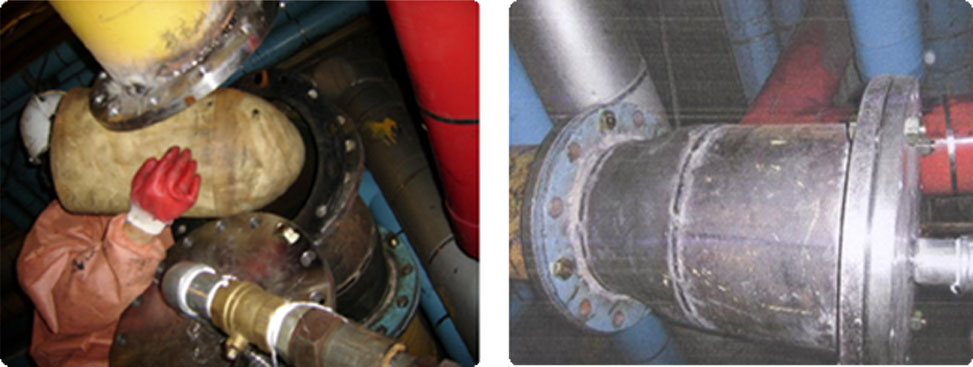

● Photographs of Equipment and Operation Site

|

Installing launcher for PIGging

Equipment for PIG Cleaning

Cleaning for Condenser and Heat Exchanger Tub

|

|

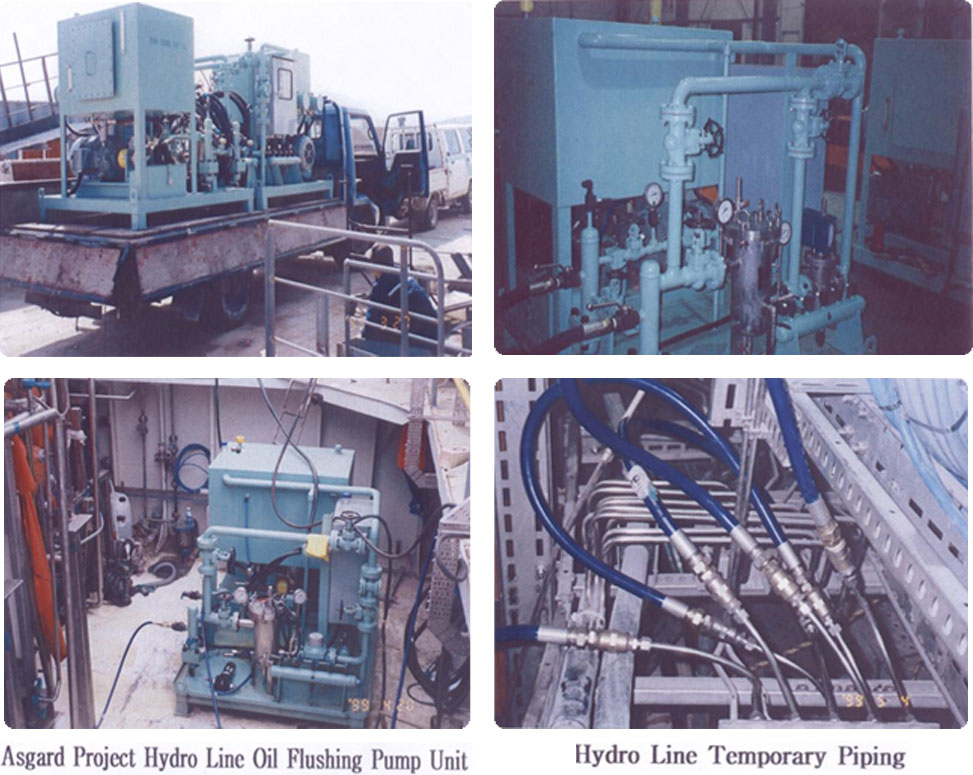

● Scope of Application

|

Fueling Line, Hydraulic Line, Grease Line, Machine Installation Line, LOU(Lubricant) Line, SUS(Lubricant) Line

|

|

● Purpose

|

Extend life of facility and secure operation safety by removing mud, scale, sand and rust chemically (flushing oil) inside of equipment installed at plant site and of various mechanical pipes

|

|

● Operation Procedure of Chemical Cleaning

|

Picking → Flushing Circuit Configuration → Inspection: extinguishment pipe system → Oil Injection → Fist Flushing → Examination → Oil Excretion → Tank Cleaning → Main Circuit Configuration → Main Oil (Second Flushing Oil) Injection → Second Flushing → Examination → Pressure Test → Test Operation

|

|

● Check points when working with FLUSHING

|

1) Thoroughly check the configuration of the FLUSHING preparation circuit.

2) Accurately calculate and prepare the amount of FLUSHING OIL.

3) The FLUSHING PUMP selection should be selected with a capacity that fully considers friction loss based on the length, diameter, etc. of the PIPE.

4) The FLUSHING TANK sufficiently cleans the inner surface before filling to completely remove various SCALEs remaining in the TANK.

5) The FILTER for FLUSHING is assumed to have an effective area sufficient for the capacity. The RETURN tube is capable of being drunk and out of the tube.

6) Install the FILTER auxiliary network to prevent the FILTER from being damaged. Keep the OIL temperature in the tank between 50 and 80℃.

|

|

● Equipment and Field Photographs

|

OIL FLUSHING PUMP

OIL FLUSHING INSPACTION

|

|

|

|